Special In-house Processing & Full Inspection and Sorting

For the processing and inspection of important safety parts for automobiles, our Zhuhai branch is equipped with specialized machines to perform special processing and tests such as Honing Processing, Lapping Polish Processing, special Leak Tests, and Inspection using optical image microscope.

We are always taking one step forward toward customer satisfaction.

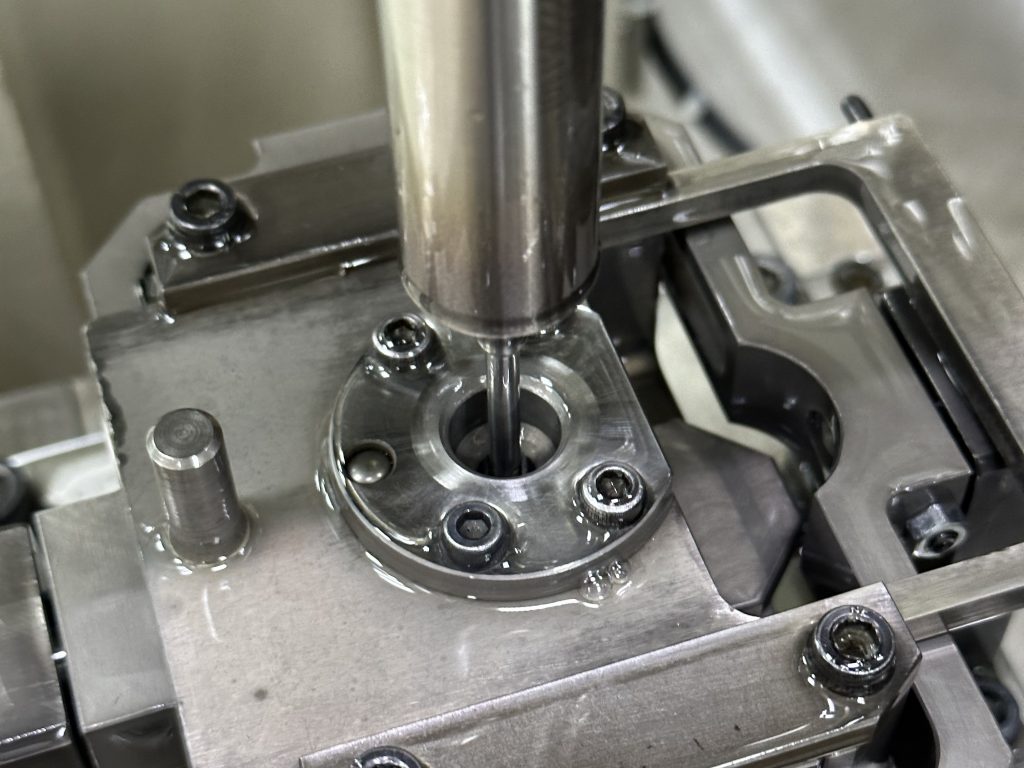

Honing Processing

Honing is a process that polishes the inner surface of cylindrical machine parts with high precision.

This finishing method can produce machine parts in which high-precision fitting are required such as cylinders and gears.

Our Honing process can be performed at following precision standards:

Inner diameter accuracy: 5μm; Cylindricity: 1μm; Circularity: 0.5μm; Surface Roughness: Ra0.3μm

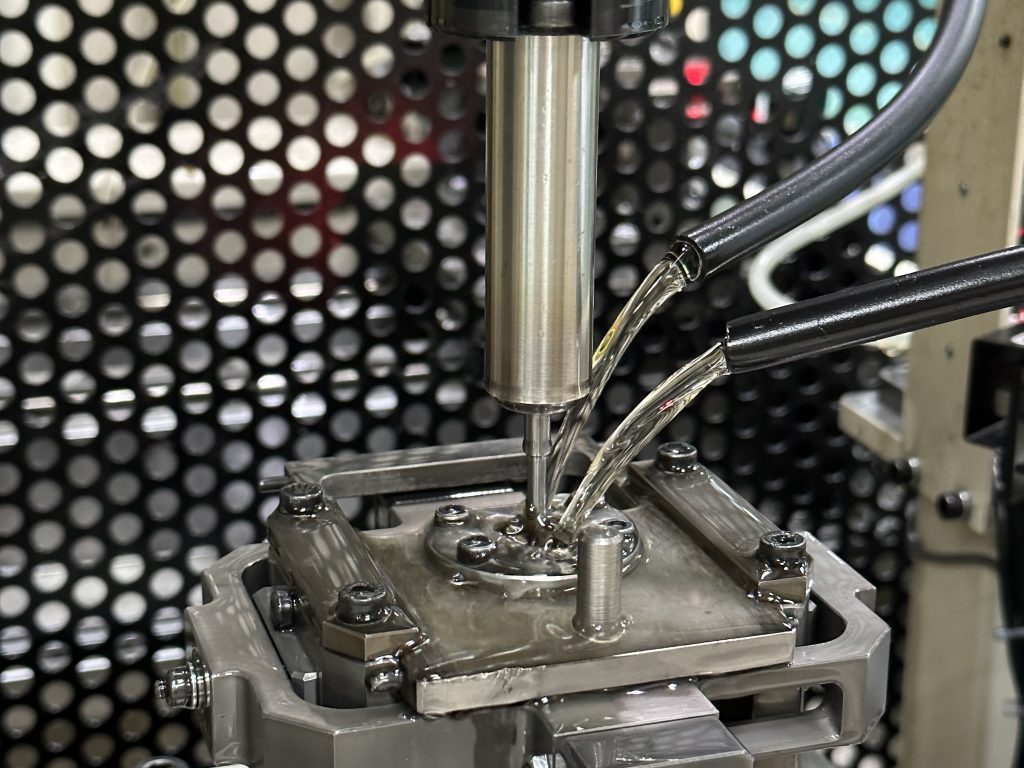

Lapping Polish Processing

Lapping polishing is a process that refines flatness. It has a distinguished characteristic that the top and bottom (both sides) are processed at the same time. This simultaneous processing of the top and bottom surfaces also improves the accuracy of parallelity of the surfaces of the material. Moreover, by using different whetstones, mirror finish can also be rendered. Lapping polishing is performed by applying pressure onto the material and the rotation of whetstone. The surface finish of your choice will be produced by a combination of whetstones, abrasives, rotation speed, and processing time.

Flatness at precision of under 0.3 μm can be processed by Lapping.

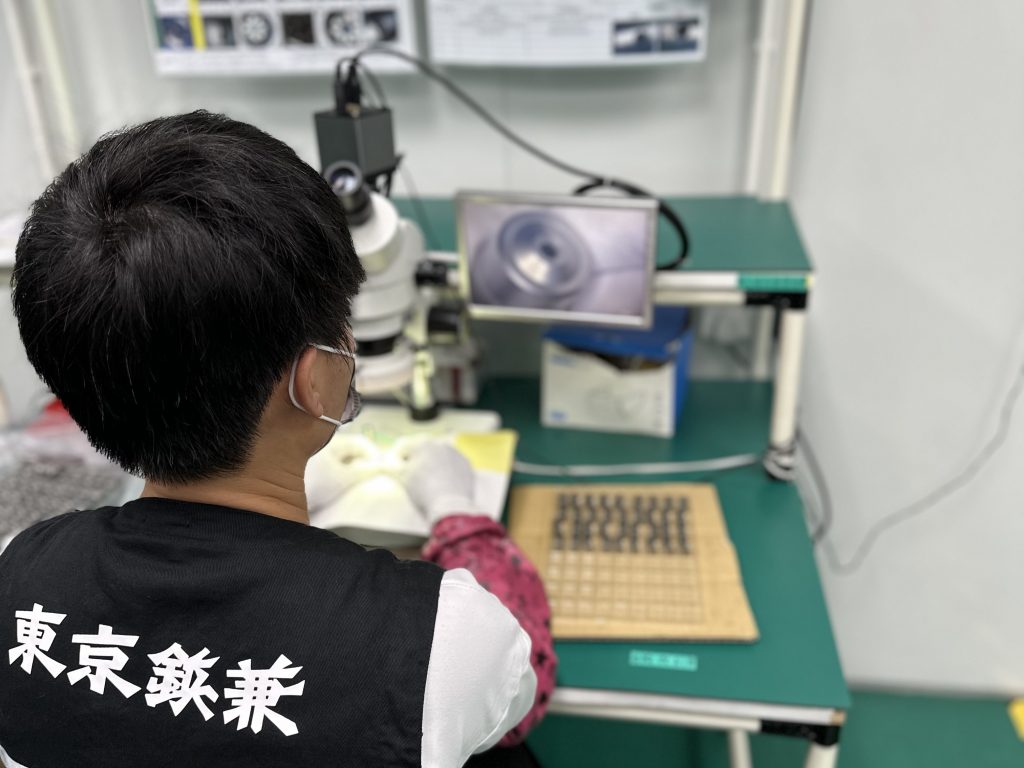

Leak Test and Full Inspection

We cater to on-demand specific tests such as Leak Test (vacuum and air leak tests), and sorting with optical image microscope. Our specialized machines can perform auto-sorting for Leak Test, and our optical image microscope inspection detects burrs at size of 5μm. We are going above and beyond to ensure we fulfill our customers’ requirements for high precision applications.