Screws and other fastening parts are indispensable to industrial products in daily life. There is a good likelihood that the very products around you contain our fastening components. For example, your mobile phone, watch, TV, DVD player, camera, printer, and the computer you are using are all assembled with screws and other products. Below is the list of the various types of products we provide.

JIS, JCIS Standard Screws of all sizes

While we are always striving to take one step ahead of the industry in product innovation, we have developed a substantial range of JIS/JCIS standard products. Not only do we supply JIS/JCIS products according to customers’ orders, we have the expertise to go above and beyond, and provide the best fastening solution to customers if needed.

Precision Screws

Since the adoption of JCIS (Japan Camera Industry Standard), the No. 0 screws developed by our company have been utilized rapidly in various fields. Then, the No. 00 screw, which was born in response to the demand for “more precise screws”, has been highly evaluated in terms of quality, accuracy, groove shape, and cost. The No. 0 and No. 00 screws, small as they are, can be regarded as the corner stone of our company. They have contributed to the improvement of the performance and cost reduction of various precision machines.

Thread-forming Screws

With the unique triangular “rice ball” shape, the TAPTITE self-tapping screw with innovative fastening technology is characterized by low torque and strong fastening force, it has a wide range of applications, and can reduce the generation of dust when drilling in. We have No. 0 TAPTITE self-tapping forming screws, as well as TAPTITE self-tapping forming screws for different materials such as resins, thin plates, and lubricated steel plates. We have a wide variety of products to meet various needs.

Specialized Cold Heading Process

With our specialized cold heading processing technology, we can achieve stable mass production of complicated parts that involved cutting and assembly in the past. Cold heading processing technology produces top notch integrated molding with minimal deviation. The unique fibrous structure and hardening process allows it to be tuned to meet various higher requirements.

Recess

Recess that accurately transmits torque allows the screws to be tightened with high torque efficiently without coming out accidentally. The drive part has a special shape which is also beautiful to look at, that prevents tampering with areas where screw removal is prohibited. We can propose the most suitable products according to customers’ application and purpose, such as the highly versatile cross-recessed screws in Japan that features good fastening performance and recyclability.

Springs

Springs are more than just a simple “shrink and stretch” component, it takes years of technical know-hows to produce springs that matches the increasingly high standards of precision and functions for industrial applications. We have factories in China (Shanghai) specialized in production of high-precision, high-quality springs.

Metal Stamping

We are experienced in producing metal parts by stamping, allowing us to produce exceptionally small parts and complicated shapes. Our products are used for a wide range of applications in various industries, especially in precision mechanics field such as cameras and watches. We can accommodate flexibility in small quantity production balancing by unit price.

Anti-loosening Fasteners

The key to fastening technology is “the endless pursuit in the study of loosening”. Being able to tighten with high torque alone does not make a perfect fastener, but it must also not come loose over time. Our screws are designed to hold firm as ever for years, yet they are removable, making them ideal for recycling and reuse. We offer a wide variety of “anti-loosening parts” with our own ideas and ingenuity to meet diversifying needs.

Processing by Cutting

In order to meet the increasingly complicated needs of cutting processing, our factories are equipped with state-of-the-art processing machines which can carry out small-lot processing for high-precision parts. Our machined parts are applied in fields that require ultra-precision, such as information processing systems that are now indispensable for social life, various shafts for audio products, and leadscrews for audio and multimedia.

High-precision Die-cast Products

High-precision die-cast parts are increasingly popular substitutes to special-shaped parts that are used to be produced by cutting and stamping. If you require something that is more complicated than conventional products, feel free to contact us to check on our die-cast products.

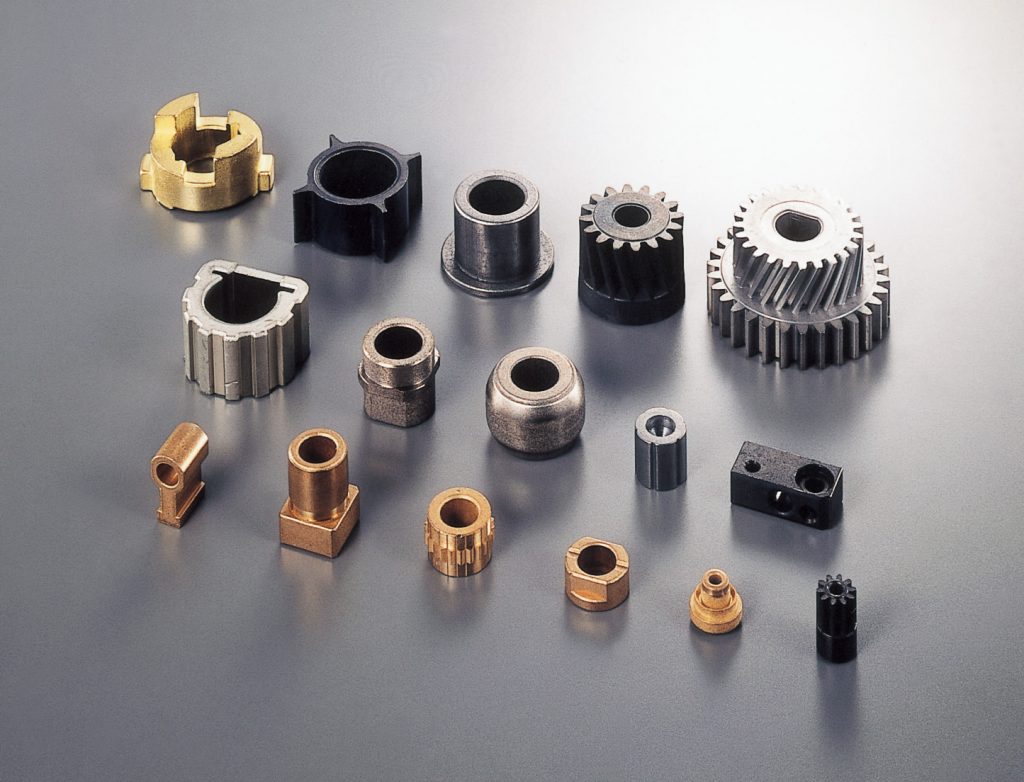

Sintered Metal Parts (Powder Metallurgy)

Sintering of metal is a processing method that involves pressing powdered metal into a specific form, and applying heat to bond the metal particles within the designed part so it will hold its new shape. Sintered metal parts are widely used in various fields.

Resin molded Parts

Based on customers’ needs, we can offer solutions of resin composites with metal parts, such as using insert and outsert molding, to provide parts that suit the application best. Please feel free to contact us from the design stage. Our many years of experience and extensive knowledge will surely be of use to you, from mold design to confirmation of molding conditions.

Factory Automation Systems

The pinnacle of our fastening technology – we are able to build extraordinarily flexible automation system owing to our expertise in fastening technology. Our professionals who are familiar with fastening parts will follow up the whole process, providing one-stop service from design conception to manufacturing site management. Our FA systems are designed to optimize productivity, cost, quality and precision from the most basic core structure for you. From as small as a drill bit to as large as the entire production line system, you are welcome to send us an enquiry at any time.